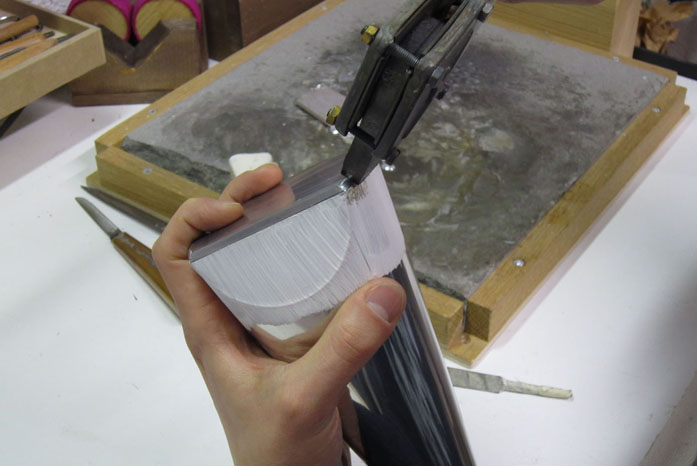

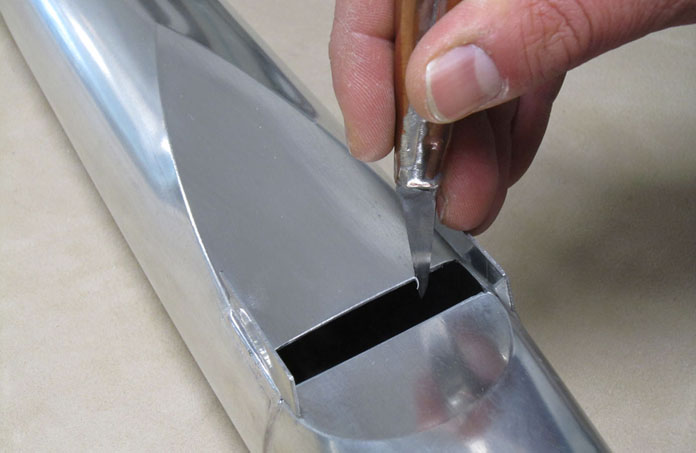

The attention that we give the stages of constructing an instrument, from design through to testing, is the guarantee of a high quality product intended to endure the test of time.

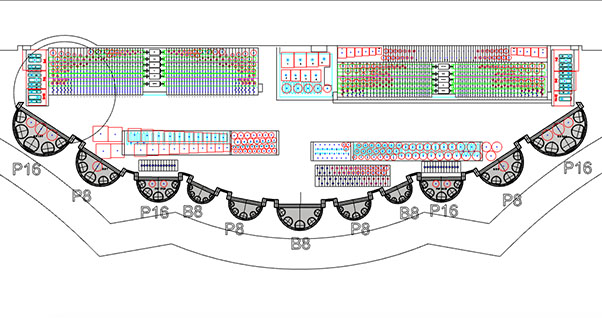

Windchests, bellows, actions, metal and wooden pipes, castings, ornamental details, structures and cabinets handcrafted by skilled hands with the help of state of the art equipment are the result of the union of tradition and innovation which has always been our inspiration.